Gentex Hollow Wall PE Spiral Pipe

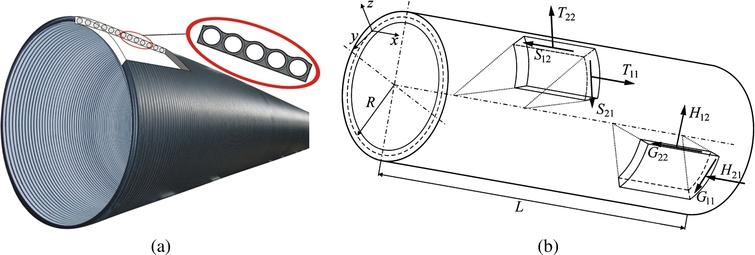

Gentex was one of the first companies to establish a Hollow Wall PE Spiral Pipe manufacturing plant in East Africa. The pipe size range from 500mm to 1500mm, they have a high ring stiffness and a high burnt intensity. Gentex Culvert pipes are manufactured in accordance to the European standard ENV13476.

The pipes have a life span of more than 60 years. The excellent abrasion resistance and flexibility of the PE-material allows the pipe to be truly multifunctional with several benefits such as, low cost assembling, easy transportation, high durability and resistance to corrosion to substances such as acid, alkali and salt.

The Gentex Hollow Wall Pipe is manufactured using prime quality high density polyethylene which, is the material used for both pressure and gas pipes.

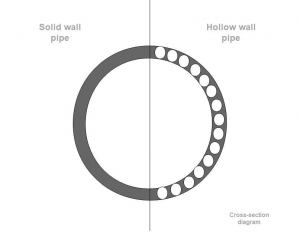

What is a Hollow wall Spiral Pipe?

As the name suggests this pipe has a hollow wall feature. These pipes are usually available in large diameters of 500mm to 1500mm.

A hollow wall pipe has a smooth inner surface to allow for a higher flow rate which enables water to drain much faster.

This hollow feature gives the pipe a much superior ring stiffness like similar solid walled pipes. This aspect is beneficial for pipes that are used in outdoor applications as they need to have a strong structure.

The difference between the hollow spiral pipe and a solid pipe is that, the spiral pipe tends to utilize less plastic material. Therefore large diameter spiral pipes are more cost efficient to produce furthermore, they are lighter and cheaper to transport.

Applications of GENTEX Hollow Wall Pipe

- Building water supply and drainage

- Road culverts

- Industrial waster application

- Storm water supply and drainage

- Rail culverts

- Agricultural drainage

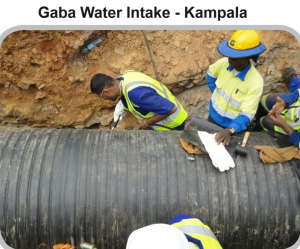

- Clean water intake

Features

These pipes are durable, highly resistible to chemical properties, have a higher flow rate, cost effective and have a high tolerance to external loads.

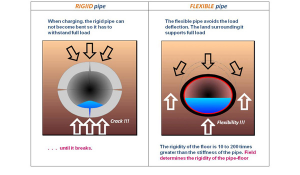

The pipe is very flexible when buried underground and will deflect any external load i.e. traffic or ground water as opposed to a rigid cement pipe. Of course the level of flexibility will depend on the support of the surrounding soil as well as the stiffness of the pipe. The flexibility does mean the pipe can deform over time however, a rigid pipe will not deform due to external pressure but it will crack rather than deform over time.

How to Install and Join

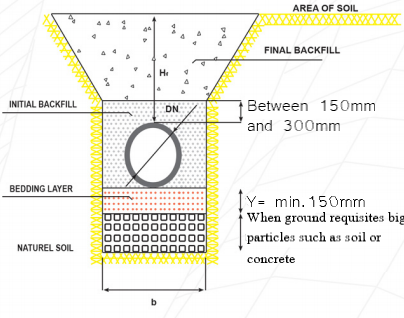

The pipe is Light weight easy to handle and install. They require less excavation area and less amount of sand filling after installation compared to other types of pipes.

The first stage of installing such a pipe on land is known as the pipe bedding. This area should be free from any large stones, a 150mm thick bedding layer should be prepared and compacted on the trench bottom. The width of the bedding should be 400m wider that the diameter of the pipe.

The second stage is known as the initial backfill. This consists of friction soil and should cover the whole width of the trench. The initial backfill should be carefully spread furthermore, it is important to note that compaction of the soil should be done in layers of 150mm around the pipe. No compaction should be done on the pipe until the backfill is 300mm above the pipe crown.

The final backfill should be free from stones, dug material is better for compaction which should be carried out in several layers. The material used for the final backfill will differ between traffic load areas and non traffic load areas.

Pipes have a good result in welding therefore ensuring leakproof joints. The pipes can be welded using a hand held extrusion machine or a heat shrink belt.

Hollow Winding Pipe Fittings and manholes.

Gentex also manufactures Hollow Pipe Manholes as well as their fittings. These manholes have several benefits as opposed to their traditional counterpart.

Benefits of Gentex Hollow Pipe Manholes

- Corroision resistant

- Superiroir abrasion resistnce

- Leak proof

- Pre Fabricated results in faster installations

- Can be customized

- Economical

These Manholes are used for landfills, mining, sanitary sewers, storm drains, hydroelectric and inspection chambers etc.